ParaPicker® Pick&Place

Overview

ParaPicker® PP02 are super-dynamic, dual-axis, parallel kinematic Pick&Place systems with linear drives.

♦ the history

In 2005 we developed a dual-axis, parallel kinematics robot, which used linear direct drives as actuators. Back then, our parallel-kinematic CF rod design already showed the industrial standards of today.

This was the begining of our ParaPicker® technology!

ParaPicker® PP02 Pick&Place are the development to the industrial product and are based on our established HighDynamic® linear motor modules. In 2013 PP02 was first introduced at the MOTEK fair in Stuttgart.

See the presentation on the right.

♦ the name

- Para stands for the parallel arrangement of the actuators

- Picker stands for the typical tasks

♦ the advantages

- the dynamics in Z-axis direction

- the force in X-axis direction

- very slim design

- no moving cables

- low reaction forces & vibration

- the price

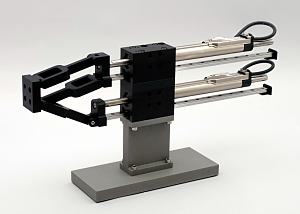

ParaPicker® Pick&Place PP02-23x160

Characteristics:

- dual-axis parallel kinematics Pick&Place system

- 137 N peakforce per actuator

- width only 44 mm

- built with standard HighDynamic® linear motor modules

- typ. work surface in X-Z 150 x 80 mm

- typ. speed 3 m/s

- typ. acceleration 50 m/s²

- typ. payload up to 500 grams

- all joints & ball carriages sealed

- positioning repeatability +/- 0,3 mm

- one cable technology

- suitable positioning controller from LinMot® range

- connection to all major controls e.g. over parallel I/O, CANopen, Profibus-DP, Ethernet TCP/IP, EtherCAT, PofiNet, PowerLink oder SERCOS III is possible

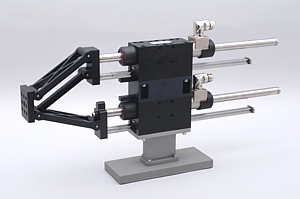

ParaPicker® Pick&Place PP02-37x120

Characteristics:

- dual-axis parallel kinematics Pick&Place systems

- 255 N peak force per actuator

- width only 60 mm

- built with standard HighDynamic® linear motor modules

- typ. work surface in X-Z 240 x 90 mm

- typ. speed 3 m/s

- typ. acceleration 50 m/s²

- typ. payload up to 2.000 grams

- all joints & ball carriages sealed

- positioning repeatability +/- 0,3 mm

- one-cable technology

- suitable positioning controller from our LinMot® range

- connection to all major controls e.g. over parallel I/O, CANopen, Profibus-DP, Ethernet TCP/IP, EtherCAT, PofiNet, PowerLink oder SERCOS III is possible

Options

- linear motors with wipers for rough environments (only PP02-37)

- special wipers for environments with very fine dust (only with PP02-37)

- linear guides with reinforced wipers

- more efficient design with our HighDynamic® 48er-modules

- pneumatic brake for vertical applications

- MagSpring® adaptor for weight force compensation in vertical applications

ParaPicker® Positioning Controller

For our Parapicker® Pick&Place systems, we preferably use controllers out of the LinMot® range.

Characteristics:

- 24 VDC logic supply

- 48 - 72 VDC power supply

- 8 - 32 A output current

- selection of positioning tasks with freely definable motion profiles over I/O’s or fieldbusses

- oscillating motion

- analog position target 0 - 10 V

- pulse & direction inputs

- master-booster or gantry mode

- master-encoder synchronization

- streaming mode

- input for external high-resolution positioning sensor

- variable homing modes

- Safe Torque Off (STO)

- fieldbusses EtherCAT, POWERLINK, PROFINET, SERCOS III, TCP/IP, Profibus-DP, CANOpen, DeviceNet

- licence-free configuration tool LinMot-Talk

- controller configuration according to motor and application data

ParaPicker® Pick&Placer - Download Center

Brochures & Data Sheets

> ParaPicker® Pick&Place overview

> ParaPicker® PP02-23 data sheet

> ParaPicker® PP02-37 data sheet

Installation, Maintenance & EC Guidelines

> Installation guide, maintenance instructions & declaration of conformity - PP02-23

> Installation guide, maintenance instructions & declaration of conformity - PP02-37

Copyrights

Our texts, images, graphics, videos and sounds are subject to the protection of international copyright laws! For trademarks of others, see our copyrights.