News

New Brake Choppers for 24 VDC & 48 VDC

+++ October 23nd 2024 +++

Braking unit for 24 V and 48 V DC-bus systems

We have developed the stand-alone brake choppers BC01-24/520 and BC01-48/540 as an accessory for electric drive-systems. These products are intended for applications with 24 V or 48 V DC-Bus circuits. The internal electronics is supplied directly from the DC-Bus voltage.

Large loads, braking from high speeds and lifting applications, the BC01 are the ideal product for dissipating excess braking energy.

Typical applications

- Lifting drives

- high speeds and large moving masses

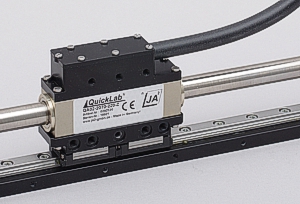

Our new QuickLab® kid!

+++ 17th April 2022 +++

Only 18mm wide! Our QuickLab® modular system has been expanded to include a small linear motor module - super dynamic and LinMot® system compatible.

The new QM02-1247 QuickLab® linear motor module has a peak force of 10.5 N, a continuous force of 3.6 N and is available with strokes of up to 120 mm.

Typical applications

- Expell

- Slide over

- Group

- Check & test

Now comes our 16 mm mini swivel tot!

+++ March 31th 2022 +++

Only 16 mm in diameter and only 62 grams in weight! The ForTorque® modular system has been expanded by a sixth size - super dynamic and LinMot® system compatible.

The new ForTorque® swivel / rotary module FT01-1643 has an output diameter of only 16 mm. Built in classic servo technology (high-speed servo motor with planetary gearbox with little backlash), it offers a torque of 0.3 Nm at a speed of 280 rpm. The ideal actuator for swiveling and screwing applications with torque monitoring via the motor current consumed.

Typical applications

- assembling

- swiveling

- screwing on and off

- closing

- winding

- bending

- testing

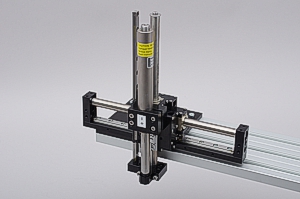

Our smallest LinTorque® Combination!

+++ November 6th, 2021 +++

Our new ForTorque® FT01-2043 has a diameter of only 20 mm and it weighs only 110 grams! A LinTorque® combination with our new QuickLab® modules is ideal. Because they are only 22 mm wide.

This new LinTorque® combination offers strokes of up to 160 mm with a peak force of 28 N. The matching ForTorque® swivel/rotary axis with the FT01-2043 offers a torque of 0.62 Nm at a speed of 280 rpm. The ideal actuator for swiveling and screwing applications with torque monitoring via the motor current.

Typical applications

- mounting

- swiveling

- capping

- sealing

- testing

New Brake Choppers for 72 V DC-Bus Systems

+++ October 22nd 2021 +++

Braking unit for LinMot® controllers of B1100, C1100 and C1200 families.

We have developed the stand-alone brake choppers BC01-72/640 and BC01-72/1300 as an accessory for our system power supply series. This product is intended for applications with 72 V DC-Bus circuits. The internal electronics is supplied directly from the DC-Bus voltage.

Large loads, braking from high speeds and lifting applications, the BC01-72 is the ideal product for dissipating excess braking energy. The BC01-72 is the ideal complement for the LinMot® controllers of the B1100, C1100 and C1200 series that do not have internal brake chopper electronics.

Typical applications

- Lifting drives

- high speeds and large moving masses

Our slimmest ForTorque® swivel!

+++ September 26th 2021 +++

Only 20 mm in diameter and only 110 grams in weight!

The ForTorque® modular system has been expanded to include a fifth size - super dynamic.

The new ForTorque® swivel / rotary module FT01-2043 has an output diameter of only 20 mm. Built in classic servo technology (high-speed servo motor with planetary gearbox with little backlash), it offers a torque of 0.62 Nm at a speed of 280 rpm. The ideal actuator for swiveling and screwing applications with torque monitoring via the motor current consumed.

Typical applications

- assembling

- swiveling

- screwing on and off

- closing

- winding

- bending

- testing

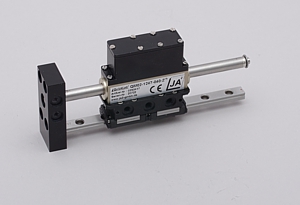

QuickLab® is our new small construction kit

+++ May 30st 2021 +++

The QuickLab® construction kit is a mechatronic system of linear motor modules and guides. The level of performance is in lower dynamic area!

The new QuickLab® mechatronic kit consists of very easy to combine linear motor modules and guides. QuickShaft® modules and guides are available with peak forces up to 28 N. At low pay loads acceleration up to 5 g and peak speed up to 3 m/s are realizable. In applications under conditions of protection class IP20 an ideale actuator set for handling, mounting and testing systems.

Typical applications

- handling

- mounting

- pick & place

- testing

MagStop® the Magnetic Parking Brake

+++ April 15th 2021 +++

MagStop® is a magnetic parking brake fitting to our 'Quick' actuators!

In vertical applications with QuickShaft®-, QuickDynamic®- and QuickLab®-actuators a simple gravity force compensation or a simple clamping system is needed.

Due to payloads in the range of a 1 gramm up to 1 kg this system must be simple, small and cost effective.

In combination with LM1247 and LM2070 linear motors MagStop® now offers a magnetic parking brake.

If the actuator is in parking position an adjustable holding force is available. In case of electric power fail a fall down of the moving components is prevented.

Typical Applications

- Quick-products

- vertical applications

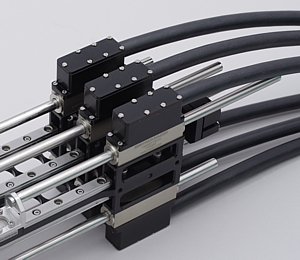

New Connector for QuickShaft® LM2070 Linear Motors

+++ April 14th 2021 +++

A brand new connector system for QuickShaft® LM2070 linear motors is announced!

The new Z-connector features a direct adaption of trailing chain cable to the QuickShaft® LM2070 motor family. With max. cable length up to 30 m QuickShaft® Drives are now suitable for industrial automation applications.

> QuickShaft page

New Connector for QuickShaft® LM1247 Linear Motors

+++ December 18th 2020 +++

A brand new connector system for QuickShaft® LM1247 linear motors is announced!

The new Z-connector features a direct adaption of trailing chain cable to the QuickShaft® LM1247 motor family. With max. cable length up to 30 m QuickShaft® Drives are now suitable for industrial automation applications.

> QuickShaft page

PosiPac® - Faster at Reduced Cost

+++ May 01th 2020 +++

Power Supply & Motion Control

PosiPac® are positioning systems that are assembled on a 4-column (PAC's) universal mounting plate ready for use. They can be delivered as pre-wired 1 to 3-axis systems. In the combination of power supplies with LinMot® controllers of series C11XX and C12XX, a DC-bus voltage of 48 VDC or 72 VDC is available. A version with an integrated 24 VDC logic supply is also suitable for supplying peripheral devices. The wiring, installation and time effort for an autonomous motion control system is significantly reduced with PosiPac®.

Typical Applications

- stand alone motion control systems

- stand alone high speed automation

- compact systems

- 1- to 3-axes applications

- world wide use

- UL-applications

ForTorque® rotary modules with rotary joints

+++ April 20th, 2020 +++

The ForTorque® modular kit has been expanded by a new size. The FlowTorque® fluidic rotary joints, which are also new, are integrated in this product!

Our new ForTorque® swivelling rotary module FT01-4050 has an outer and output diameter of only 40 mm. It's super light in weight! Build in classic servo technology, with a high-speed servo motor and with a backlash-free harmonic gearbox, it offers a peak torque of 4.0 Nm at a speed of 150 rpm. It is the first ForTorque® swivelling rotary module that is equipped with the FlowTorque® FW01 fluidic rotary joint. With its innovative sealing technology, it has an extremely low frictional torque, even under pressure conditions. This ensures a long lifetime under dynamic operational conditions.

The ideal rotary actuator when pneumatic grippers are used in handling and screwing applications.

Applications:

|

|

Wiper Set for MagSpring®'s

+++ December 7th, 2017 +++

MagSpring® magnetic springs are now available with a wiper set for rough environments.

Now, our handling systems are not only suitable for vertical applications, but for rough environments as well.

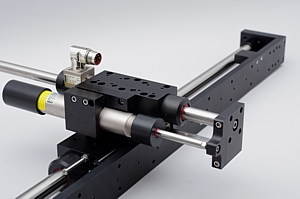

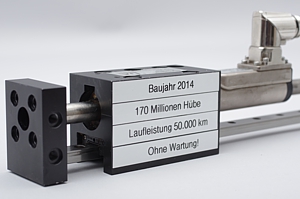

HighDynamic® Modules - In Use for Eight Years - 24/7!

+++ March 09, 2017 +++

HighDynamic® - Made for Eternity?

Highly dynamic & in action since 2009 - these are the marathon sprinters!

No maintenance & no failure/breakdown!

Unbelievable?

This speaks for our 20-year experience with high-dynamic linear motor systems.

A practiacal example (see foto on right):

HighDynamic® linearmotor modul

HM01-23x80/160

delivered 2014

170 billion of strokes

milage 50.000 km

without any maintainance!

Sales Meeting 2017 in Iphofen

+++ February 24, 2017 +++

The first annual sales meeting took place in the franconian wine village Iphofen.

After a proper wine tasting experiences were exchanged and plans for the future were made.

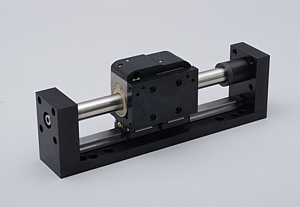

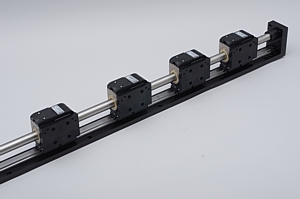

HighDynamic® Linear Motor Guides HA02-37Sx60

+++ January 04, 2017 +++

The new 'S'-version (short) of the linear motor guides HA02-37Sx60 is out now!

HighDynamic® HA01 linear motor guides, in size 37, have been expanded by the product range HA02-37Sx60 erweitert.

The 'S' stands for short, the length of the carriage. The guides are particularly short and, for example, only have an overall length of 290 mm with a stroke of 160 mm, which offers constructional benefits over pneumatic linear guides. Peak force is 122 and version with a peak force of 255 N is also available. The available option with wipers is especially suitable for rough environments. For distributing, grouping, sorting and defering applications, several independent carriages can be randomly arranged on one guide. The smallest possible distance from one carrage center to the other is 90 mm.

|

|

Over 20 Brands

+++ December 24, 2016 +++

Over 20 product names registered as brands!

Over 20 of our products and their product names are registered and trademarked as brands.

Online identical URL's with www.productname.de refer directly to our product website.